2025 What to take into account when buying Chinese carbon bicycle rims?

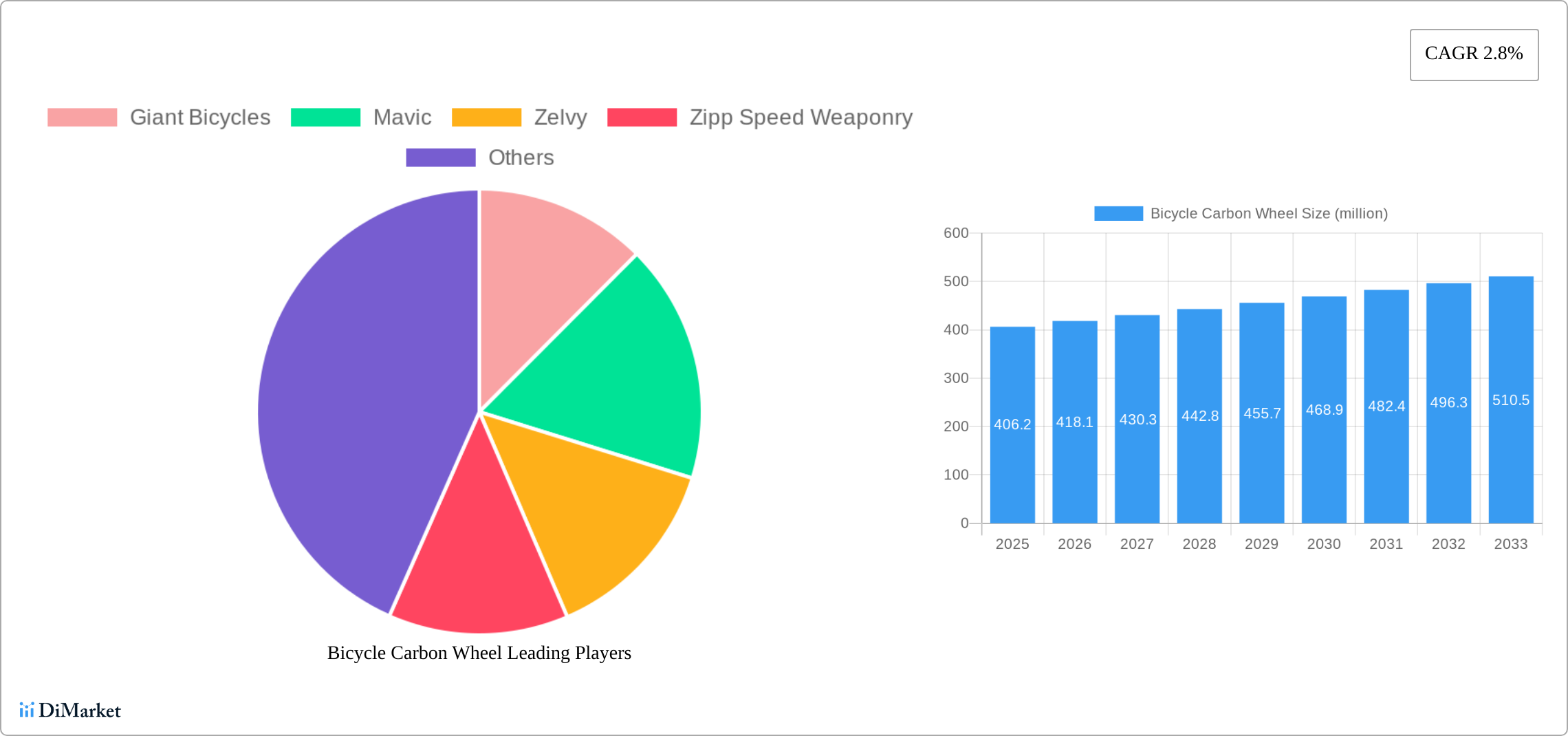

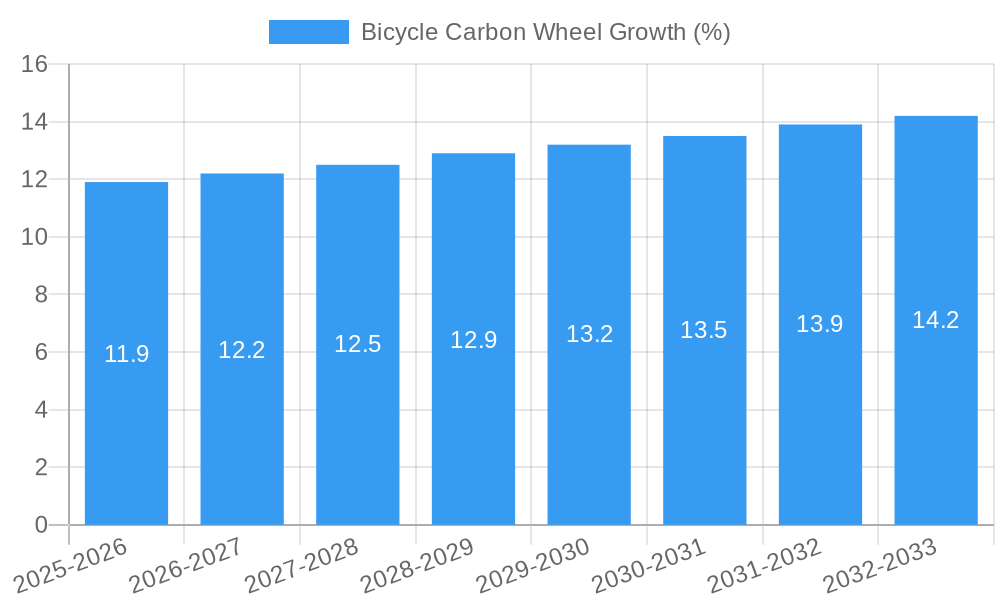

With the continuous growth of the global cycling market, carbon bicycle rims have become an essential component of high-end cycling equipment due to their lightweight, high stiffness, and aerodynamic advantages. Especially in the fields of mountain biking and road cycling, the demand for carbon bicycle rims continues to rise. According to market research, the global carbon fiber bicycle rims market is estimated at approximately $406.2 million in 2025 and is expected to grow at a CAGR of 2.8% by 2033.

China, as one of the main production bases for carbon bicycle rims globally, has attracted significant attention from international buyers due to its mature manufacturing technology and cost advantages. However, when choosing a suitable supplier, buyers must consider multiple factors to ensure product quality and service reliability.

1. Choosing the Right Supplier: TRIPS’ Advantages

Xiamen TRIPS Sporting Goods Co., Ltd., founded in 2017, specializes in the R&D, design, production, and sales of carbon fiber bicycle rims and composite materials. The company has a production area of over 2,000㎡, staffed with 6 engineers and more than 40 well-trained workers. The monthly production capacity reaches 3,000 carbon bicycle rims and 500 pairs of wheelsets. All products are strictly tested under the international ISO4210 standard to ensure quality and reliability.

TRIPS’ carbon mountain bike rims and road bike rims carbon series cover a wide range of cycling needs. The company adheres to the business philosophy of “Quality Development, Reputation, and Survival,” striving for excellence throughout product development and production.

2. Key Factors to Consider When Buying Carbon Fiber Bicycle Rims

1. Material & Manufacturing Process

The performance of carbon bicycle rims directly depends on the quality of materials and the manufacturing process. High-quality carbon fiber raw materials feature high strength and high modulus, meaning the rims remain lightweight while withstanding high stress during riding.

Material Source: Premium carbon fiber typically comes from Japan (Toray), China (Zhongke), Korea, and well-known European suppliers. The fiber orientation, layer design, and resin content all affect the rigidity and durability of carbon fiber rims bike.

Manufacturing Process: Methods include molding, vacuum infusion, and hot pressing. TRIPS adopts a fully automated hot-press combined with hand shaping to ensure tight lamination without air bubbles, enhancing impact resistance.

Performance Testing: Every carbon bicycle rim undergoes bending, impact, and fatigue tests to ensure safety at high speeds or on rough terrain. ISO4210 is the globally recognized standard for bicycle rim safety testing.

Practical Advice: Before purchasing, request material supply certificates and test reports from the supplier, and inspect the cross-section or fiber lamination of the rim to verify quality.

2. Rim Depth & Aerodynamic Performance

Rim depth directly affects aerodynamic performance, handling, and weight.

Deep Rims (50mm+): Suitable for road cyclists pursuing high speed and reduced air resistance. Deep rims can significantly reduce drag but may increase handling difficulty in crosswinds.

Medium Depth Rims (30–50mm): Balance aerodynamics and handling stability, suitable for most road riding and racing scenarios.

Shallow Rims (20–30mm): Lightweight and maneuverable, ideal for mountain biking and undulating terrain.

In addition, rim shape and profile curves affect airflow separation points, influencing overall drag. TRIPS optimizes rim profiles through wind tunnel testing to achieve a balance of speed and stability.

Practical Advice: Choose rim depth based on actual riding conditions (road, mountain, triathlon) rather than purely aesthetic appeal.

3. Quality Control & Certifications

Quality control is crucial to ensure the long-term reliability of carbon fiber rims bike.

International Certifications: ISO4210, EN14781, CEN standards verify the rim’s ability to withstand maximum load and impact.

Batch Consistency: High-end suppliers perform tensile and impact tests on each production batch to ensure uniform performance.

Detail Inspection: Rim surfaces should be smooth without bubbles or resin drips, and hole positions must be precise. TRIPS hand-shapes and true-runs each rim to ensure no eccentricity or noise when mounting tires.

Practical Advice: Request batch test reports and production process videos from suppliers to reduce procurement risks.

4. Supplier Production Capacity & Lead Time

For B2B buyers, a stable supply chain and reliable lead time are essential.

Production Capacity: TRIPS has a monthly capacity of 3,000 carbon bicycle rims and 500 wheelsets, meeting large-scale order requirements.

Lead Time: Supplier lead times directly affect inventory management and project schedules, so confirm timelines in advance.

Order Flexibility: Supports customized logos, rim colors, and profile curves, meeting the needs of different markets and brands.

Practical Advice: Before signing a contract, confirm production scheduling, quality inspection processes, and urgent order handling mechanisms to ensure supply chain stability.

5. After-Sales Service & Technical Support

High-quality carbon bicycle rims rely not only on the product itself but also on comprehensive after-sales and technical support.

Warranty Policy: TRIPS provides rim and wheelset warranties covering material defects and manufacturing issues.

Installation & Maintenance Guidance: Proper installation, brake system compatibility, and wheel truing affect rim lifespan. Suppliers offer manuals, video guidance, and even remote support.

Issue Response Mechanism: Quickly respond to customer feedback, providing spare parts or replacement solutions to minimize downtime.

Practical Advice: Prioritize suppliers offering full technical support, especially for cross-border B2B buyers, to reduce risks.

3. Frequently Asked Questions (FAQ)

Q1: How can I judge the quality of carbon fiber bicycle rims?

A1: Check the manufacturing process, material source, and international certifications to verify quality.

Q2: Are carbon bicycle rims suitable for all riders?

A2: They are ideal for riders pursuing lightweight and high-performance cycling. For beginners or budget-conscious riders, aluminum rims may be a better choice.

Q3: How should I maintain carbon fiber rims bike?

A3: Regularly inspect for cracks or damage, avoid impacts, and clean with a soft cloth. Do not use strong acids or bases.

4. Summary & Recommendations

When purchasing carbon bicycle rims, buyers should consider material & process, rim depth, quality control, production capacity & lead time, and after-sales support. Choosing suppliers with international certification and a strong reputation, such as TRIPS, ensures reliable products and services.

TRIPS, with advanced manufacturing and strict quality control, has become a trusted partner for global buyers. The company is dedicated to providing high-quality carbon fiber bicycle rims and wheelsets to meet diverse cycling needs.

Contact Us Now for More Information and Quotes!