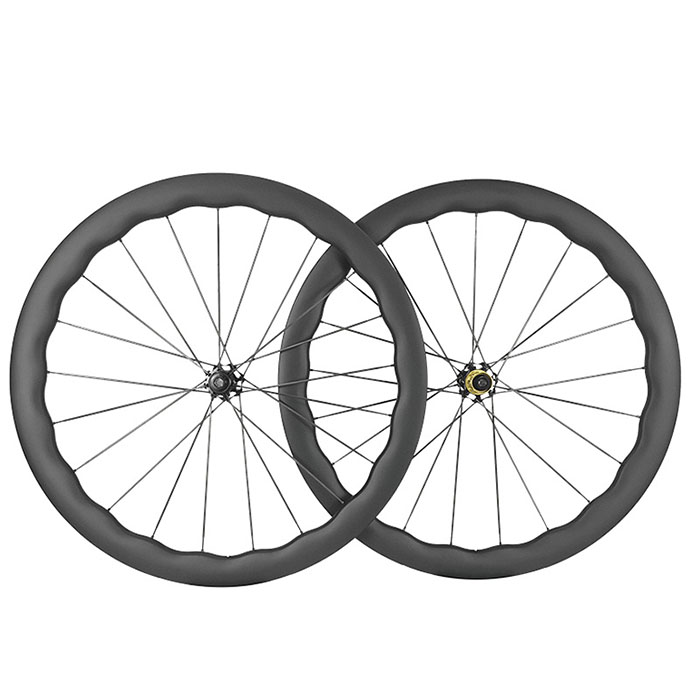

How Can I Find High-Quality Manufacturers in China That Produce 55mm Rim Height, 700c Carbon Fiber Clincher Wheel Rims?

As the global road cycling industry continues to push the boundaries of speed, efficiency, and safety, the role of carbon wheel components has never been more critical. In particular, demand for high quality 700c carbon clincher rims has surged as brands and manufacturers seek reliable partners capable of delivering precision-engineered products at scale.

Against this backdrop, choosing a High Quality 700c Carbon Clincher Rim Manufacturer China – 55mm Deep Section is no longer simply a sourcing decision. It is a strategic commitment to product performance, rider safety, and long-term brand reputation.

This article takes a closer look at how advanced production processes, rigorous safety standards, and real-world performance validation define modern deep-section road bike rims, and why manufacturers around the world continue to rely on Chinese expertise for high-end carbon rim production.

Industry Perspective: Why 55mm Deep-Section Rims Define Modern Road Cycling

In recent years, deep-section road bike rims have moved from being niche racing components to mainstream choices for competitive amateurs and performance-oriented enthusiasts. Among various depths, 55mm stands out as a highly versatile option.

From an industry standpoint, 55mm rims offer:

Noticeable aerodynamic gains over shallow profiles

Improved momentum preservation at cruising speeds

Manageable crosswind stability for real-world riding

For manufacturers and brands, 700c carbon clincher rims in the 55mm category provide an ideal balance between performance appeal and broad market acceptance. When combined with tubeless compatibility, these rims meet the technical expectations of modern frames, tires, and braking systems.

This explains the growing global interest in 55mm Road Bike Rims tubeless as a core product platform.

Manufacturing Excellence: Inside a High-Quality Carbon Rim Factory

Producing high-quality carbon clincher rims is a complex process that requires far more than raw materials. It demands consistency, engineering discipline, and process control at every stage.

Advanced Carbon Layup and Hot-Press Molding

At Xiamen Trips Sporting Goods Co., Ltd., rim production begins with precise carbon layup design. High-modulus and intermediate-modulus carbon fabrics are strategically layered to balance stiffness, impact resistance, and fatigue life.

Using hot-press molding technology, carbon layers are cured under controlled temperature and pressure, ensuring:

Uniform resin distribution

Stable wall thickness

Reduced internal voids

This process is essential for producing deep-section road bike rims that maintain structural integrity under high loads.

Material Selection: High-Modulus Carbon Fiber Advantage

Material choice directly influences weight, stiffness, and durability. For China road bike cycling rims, TRIPS selects premium carbon fibers optimized for rim applications.

Key benefits include:

Higher stiffness-to-weight ratio

Improved lateral rigidity during sprinting

Enhanced braking and thermal stability

These material decisions enable the production of 700c carbon clincher rims that are lightweight without compromising safety margins.

Safety Standards and International Testing Compliance

Safety remains a defining metric for any High Quality 700c Carbon Clincher Rim Manufacturer China – 55mm Deep Section. TRIPS rims are rigorously tested according to internationally recognized standards.

ISO 4210 and Beyond

All carbon rims undergo testing aligned with ISO 4210, covering:

Radial fatigue

Impact resistance

Spoke pull-through strength

In addition, design references and test methodologies draw from European benchmarks such as EFBE-style stress simulations, ensuring compatibility with demanding riding conditions.

For brands sourcing high-quality carbon clincher rims, this level of validation provides confidence across global markets.

Weight Optimization and Structural Balance

While weight reduction is a key selling point, responsible manufacturers understand that ultra-light designs must not compromise durability.

Typical weight targets for 55mm Road Bike Rims tubeless are achieved through:

Optimized layup schedules

Reinforced nipple beds

Controlled resin content

This approach results in 700c carbon clincher rims that perform consistently across long service lifecycles, even under aggressive riding styles.

Aerodynamic Validation: Wind Tunnel Insights

Aerodynamics is a major reason riders choose deep-section road bike rims. To support real-world performance claims, rim profiles are developed and refined using computational fluid dynamics and wind tunnel reference data.

Key aerodynamic considerations include:

Rounded leading-edge profiles for yaw stability

Smooth tire-to-rim transitions

Reduced drag across common wind angles

These design principles are especially relevant for 55mm Road Bike Rims tubeless, where wider internal widths must still maintain aerodynamic efficiency.

Technical Parameter Reference Table

| Parameter | Specification |

| Rim Size | 700c |

| Rim Depth | 55mm |

| Rim Type | Clincher / Tubeless Ready |

| Material | High-Modulus Carbon Fiber |

| Internal Width | 19–21mm (customizable) |

| External Width | 26–28mm (customizable) |

| Weight Range | Optimized for performance balance |

| Testing Standard | ISO 4210 |

| Application | Road racing, endurance, OEM builds |

This configuration positions TRIPS among leading suppliers of China road bike cycling rims for premium and mid-to-high-end markets.

Manufacturer Profile: Xiamen Trips Sporting Goods Co., Ltd.

Founded in 2017, Xiamen Trips Sporting Goods Co., Ltd. is a specialized manufacturer integrating R&D, design, production, and global supply of carbon bicycle components.

With:

A 2000㎡ production facility

Over 50 skilled staff, including 6 engineers

Monthly capacity of 3000 carbon rims and 500 wheelsets

TRIPS supports consistent output of high-quality carbon clincher rims for international customers. All wheelsets are hand-built and trued by experienced mechanics, ensuring performance accuracy and long-term reliability.

Today, TRIPS products are supplied to Europe, the United States, Japan, Korea, Thailand, and other markets, earning long-term cooperation with well-known international partners.

FAQ – Common Questions from Bicycle Manufacturers and Brands

Q1: Are the 55mm rims fully tubeless compatible?

Yes. All 55mm Road Bike Rims tubeless are designed for modern tubeless systems and tested for airtight sealing.

Q2: How do you ensure consistency across large orders?

Mold control, standardized layup schedules, and ISO-based inspection ensure uniform quality for all 700c carbon clincher rims.

Q3: What makes your rims “high quality”?

Material selection, hot-press molding, structural testing, and aerodynamic validation define our high-quality carbon clincher rims.

Q4: Can these rims be used for complete wheelset builds?

Yes. TRIPS designs deep-section road bike rims for compatibility with major hub and spoke systems.

Q5: Are these rims suitable for global markets?

Absolutely. Compliance with ISO 4210 supports international distribution of China road bike cycling rims.

Call to Action: Partner with a Proven Carbon Rim Manufacturer

If you are seeking a High Quality 700c Carbon Clincher Rim Manufacturer China – 55mm Deep Section partner who understands both engineering and market realities, TRIPS is ready to support your next project.

By choosing a manufacturer with proven expertise in 700c carbon clincher rims, you gain:

Stable production capacity

International safety compliance

Performance-driven design support

TRIPS welcomes cooperation with bicycle brands, OEM factories, and professional assemblers worldwide.

Conclusion

In today’s competitive cycling industry, performance claims must be backed by engineering discipline and manufacturing integrity. High-quality carbon clincher rims are not the result of shortcuts, but of controlled processes, validated materials, and rigorous testing.

For manufacturers and brands seeking reliable deep-section road bike rims, working with an experienced China road bike cycling rims producer ensures both product credibility and long-term success.

As demand for 55mm Road Bike Rims tubeless continues to grow, Xiamen Trips Sporting Goods Co., Ltd. remains committed to delivering carbon rim solutions that meet the highest standards of performance, safety, and consistency—mile after mile, market after market.